Prepping for Beginners: Where to Start Prepping

Where to begin prepping?

I imagine a lot of people are like me when it comes to how you were introduced to the subject of prepping. In 2007, there was no Doomsday Preppers TV show that I could look to for ideas, perspective and some humor. I wasn’t sure what I was looking for really, but it all began for me with a sense of urgency. It wasn’t like I was experiencing cold sweats at night in bed or anything like that, but I felt that as a father and husband I needed to get ready. Ready for what? I didn’t know at the time, but I would eventually figure that out.

When I first started prepping I didn’t know specifically what I was supposed to do or what prepping was to be honest – only that I felt that strong need to do something to protect my family. This was a gnawing thought in the back of my mind; like the kind you might get when you see someone whose face is familiar, but you can’t picture where you know them from. When this happens to me, I can’t really think of anything else until I realize where it is that I know that person. It usually passes, but this lingering thought that I needed to get prepared would not go away.

I started to research home security topics first because I imagined someone harming my family and that was an easy jump to make. I needed to get a gun in case of an intruder. I had small children and a wife, so this was logical I thought, but as I was shopping and researching, I entered other areas that increased the world of things I could see as potential problems.

In my mind there was doubt and uncertainty about the future and the only thing that made sense for me to do was to prepare for the worst. It never really occurred to me that I was blowing anything out of proportion or that I should just sit on my 401K until things got better because I knew that eventually bad times were coming. I had energy and a sense of purpose even if I didn’t have my wife on board at the time. I listened to a lot of voices tell me what I should focus on. I read a ton of articles and watched days of YouTube videos but I still felt more urgency than a direction. My gut told me I should be doing something, but still I had no clue where to start. Where to start prepping?

We have a lot of readers on Final Prepper who have been prepping for years. but for this post I wanted to go back to the beginning and try to share what I have learned, what worked for me and what didn’t and hopefully give you some direction that I didn’t have. I know that our readers will help by adding to the conversation in the comments below.

What Every New Prepper Needs to Know:

You are not crazy!

There are a million things we talk about on the subject of prepping, but it all boils down to this. The goal of Prepping is to keep you alive. You prepare for bad things happening in your life. Your preps are those resources (skills, supplies, gear, relationships) you have that will allow you to ride out the bad things with as little negative consequences as possible. Trying to survive isn’t crazy and making sure you have a plan for bad things isn’t nuts either.

Start with visualizing what you are concerned about

In the beginning I focused on a lot of things that I could worry about from the standpoint of my family. There was the possibility of so many things: economic collapse, tornadoes, riots, nuclear war, government tyranny, global pandemic, global warming, global cooling, peak oil, terrorism, peak water, EMP, Zombies, rabid Bigfoot…. OK, I am kidding about the last two obviously but the point here isn’t to focus on a specific threat to your life although thinking about something you are concerned about can help you plan.

Are you ready to start prepping?

How to Start Prepping

Understand what everyone needs for survival

Every human on earth needs the same basic things to live. You need water, food, shelter and security. Can you live without water? Yes, for a while depending on where you are but not for long. Can you live without shelter? It depends; are you in the desert or the mountains of Colorado? Food is probably the one thing you can live without the longest, but lack of a fairly constant source of nutrition will harm your health and make you less able to deal with other issues as effectively as you need. You could have all of these bases covered, but someone who failed to prepared might see you and want to take them away from you and give them to his family.

Read as much about prepping as you can. Learn and get different perspectives before you make snap decisions.

You need all of these survival items, regardless if zombies from outer space are wreaking havoc on earth or the stock market takes a dive and never returns. If almost any of the “threats” mentioned above happened; you can plan on disruptions in your life. They could be minor or they could last years. You can use these things to judge your preparedness level by how long you could survive if you had to count on yourself to get water. If you had to provide your own food, how much would you have? If you couldn’t call the cops would you have some means of defense?

Identify areas where you need to prepare

I think the best thing to do before you start prepping is to think about what your family needs to survive and choose a time-frame. You can start small, take two weeks to begin and start figuring out how much you would need to last for 14 days.

- Without access to water

- Without access to food

- Without access to power/heat/air-conditioning/a house

- Without the possibility of calling the police

Food and water should be simple. How much food do you need for your family and anyone else who might stop by if you had to stay indoors for 14 days? This should be food that doesn’t need refrigeration that your family eats already. How much water would you need to do the same thing? A good average is one gallon per day per person.

Two posts that might help with your food preps:

Shelter and Security get into different things depending largely on where you live and your personal beliefs in the case of firearms. They also might require licensing and in some cases a higher entry point – cost wise to prepping than food and water.

Start acquiring supplies, gear and skills

You should have at least a short list now of things you need to consider for basic survival for two weeks. How much of this do you already have? Do you have water stored? Do you need containers to store water?

- 100 Year old way to filter rainwater in a barrel

- Do you have water if the grid goes down?

- Disinfection: From Treating Water with Bleach to Killing Ebola

Take care of food and water first because that is the simplest thing to do. Once you have food and water stored for two weeks, identify other aspects you could need like security, first-aid, alternative power, fuel.

Reevaluate and adjust as necessary

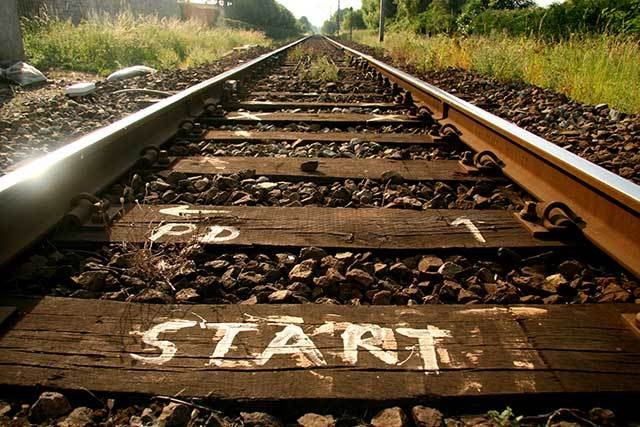

If you followed the plan above you have the basics you need to last for one week. Congratulations! This puts you ahead of 98% of the rest of your neighbors. You should have a sense of accomplishment but you may feel like you have only scratched the surface. My personal goal is to prepared to live for one year without access to food, water, the police, power or fuel. I still have a way to go in some areas, but each day is a journey for me. Some days I make great strides. Other days, I have to step back and regroup, but I am always looking down the road.

Looking back over the 8 years I have been prepping, I learned that you don’t want to jump into most prepper purchase too soon. Food and water are easy and I didn’t start buying freeze-dried food until I had 6-months of food stored in my pantry first. I didn’t go out and buy the first gun I saw, I gave some serious thought to what could afford and what would be the best gun for home defense if I could only chose one. I had a long-term plan on firearms, but I didn’t buy them all at the same time.

Ammo was another area that I constantly worked on because at some points in the last few years, you simply couldn’t buy any ammo. I had enough to start with to last me for two weeks of anarchy and built from there alongside my food, water, power and other preps. I tried to not let any single prep get too much attention and slowly grew my supplies evenly, when I could get a deal and not at the expense of something I needed more. One key to remember here is that you don’t have to have everything right now.

Relax but don’t quit

In the beginning, I was consumed with the thought of prepping and how I was so far behind the curve. Since that time 8 years ago, I have witnessed thousands of times where disaster was right around the corner only to wake up the next day to find the world still spinning. This will happen to you, but you shouldn’t give up on your prepping efforts. That is another reason not to pin your actions on a specific event or threat. The people who prepared only because of the Mayan calendar 2012 issue were likely disappointed when nothing happened but this shouldn’t happen to you.

Prepping is a lifestyle that will see you through events we might not even see coming. By preparing now and continuing slowly as your resources allow you will give yourself security. You will give your family protection and a chance at survival. You will be someone who can lead in a disaster and give hope when there might not be any left.

For more information you can start with our Prepping 101 series – How to get started prepping.

I know some of this was remedial to my experienced readers, but hope this was able to help give some perspective to those who may just be getting started prepping. Now, you can go and get someone else to join you too. Together we will make it through whatever the future has planned for us.

Where to begin prepping? I imagine a lot of people are like me when it comes to how you were introduced to the subject of prepping. In 2007, there was no